Help

Wiki

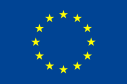

Shape recognition

The shape recognition is based on the profile of a sherd fracture represented in SVG format (D6.3). The process starts with an image of the sherd focused on the fracture and provides tools to extract the scale factor, the external and the internal profile of the potsherds. The extracted data are sent to the API Server that composes the SVG file and sends it to the Shape Recognition Model for a prediction. The results are enriched with database information and sent back to the App.

A call to the recogniser will result in 5 possible ceramic types, each with a specific probability, that the user may evaluate and eventually select and save. The overall process consists of the following sequential steps:

- Step 1: Image selection and manipulation

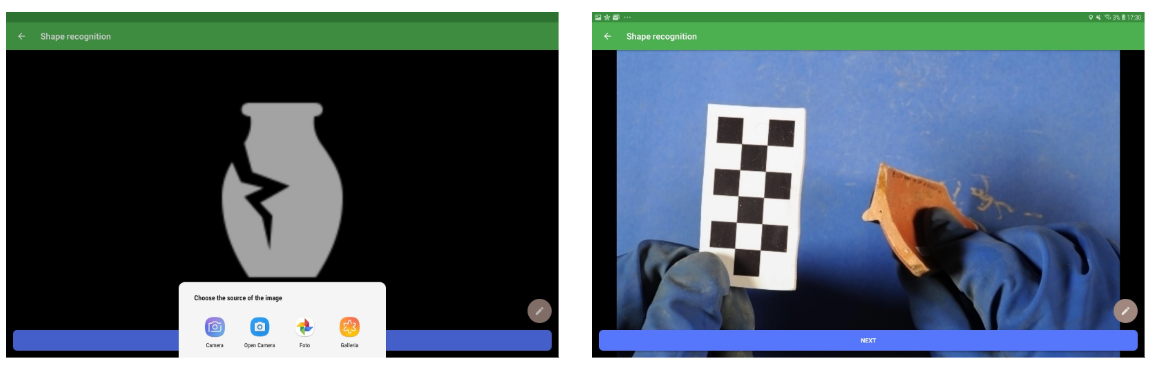

- Step 2: Definition of the scale factor

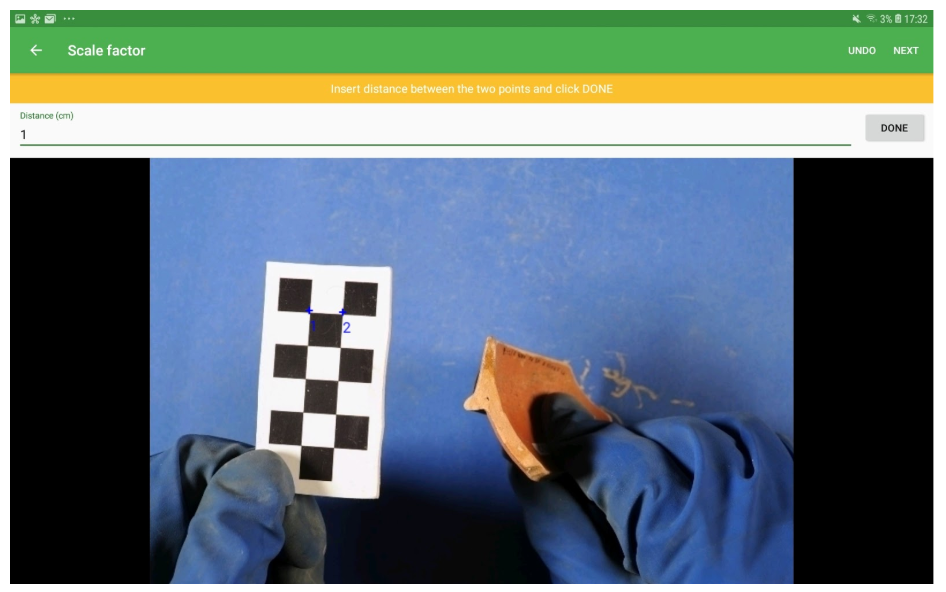

- Step 3: Extraction of the external profile

- Step 4: Extraction of the internal profile

- Step 5: Evaluation of results

- Step 6: Manual classification (alternative)

- Step 7: Save the info in a sherd (for authenticated users)

The image to be used to sketch the profile may be selected from the device galleries (i.e. previously acquired images) or taken directly with the camera. Once selected, the image may be manipulated using the tools provided by the pen button on the right bottom corner of the screen.

The expected manipulations may be:

- Flip horizontal

An important requirement is the in the final sketch the external profile must be on le left-hand side. The horizontal flipping of the image may be used at this purpose. - Rotation

The sherd fracture should be oriented in order to follow the real vessel orientation for improving the prediction probability.

It isn’t necessary to make any other special manipulations of the image because it will not be used as input to the prediction.

The definition of the scale factor is important in order to scale the image to the dimension of real vessels, helping the recognition tool in its search and retrieval task. To define the scale factor the user will be asked to select 2 points in the image and assert the distance in real life. For this reason, users must take pictures of the potsherds always with a ruler, that will have to be placed at the same level as the fractured profile.

Once the scale factor is defined the user may step forward to the extraction of the external profile. The process consists of using a finger to choose points along the external profile of the fracture. The density of the points depends on the complexity of the profile, it is important to capture all the discontinuities and curves of the profile. A smooth outer profile can be sketched with a few points. It is possible to clear the whole sketch or undo points sequentially.

After the extraction of the external profile, the user should provide the internal one using the same technique.

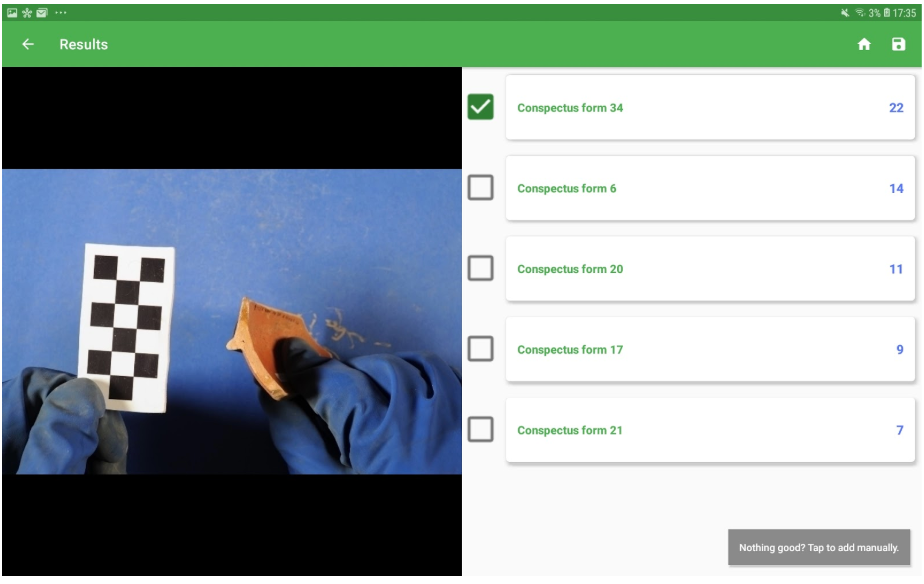

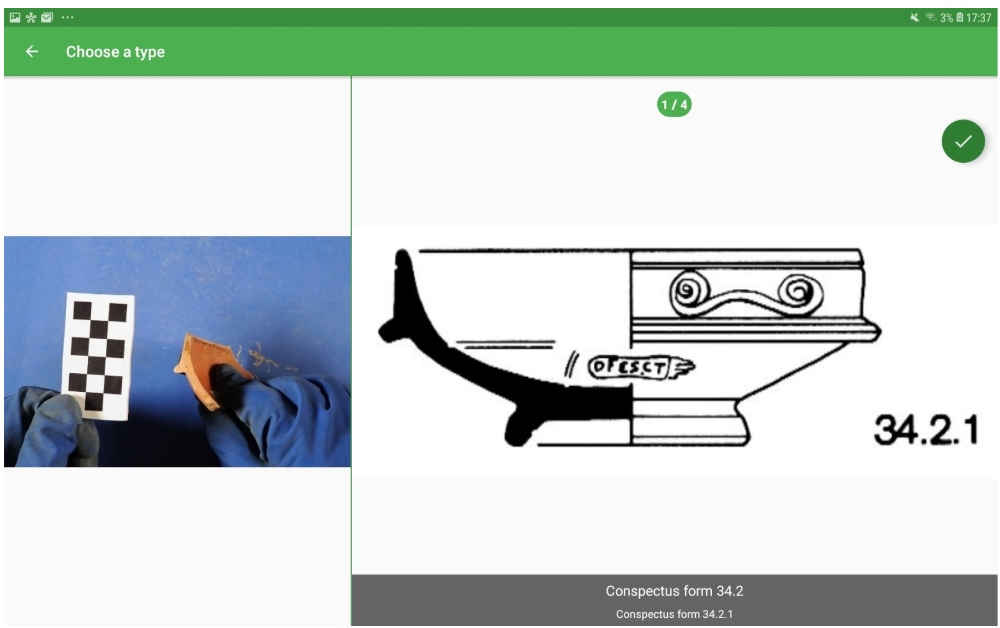

In step 5, the user may evaluate the results of the prediction. Any prediction consists of 5 ceramic types with different probabilities. Is important to note that, as ceramic types are structured in classes and subclasses, the prediction engine tries to identify only the top level classes as discussed in D5.1. For example, the class “Conspectus form 34” (see image above) is the parent of “Conspectus form 34.1” and “Conspectus form 34.2” that differ one from the other of small bits that cannot be easily captured by the neural network but that are also difficult to distinguish by humans.

As already explained for the decoration recognition, if the user isn’t happy with the prediction may proceed manually tapping on the button “Nothing good? Tap to add manually” and enter the visual matching interface. In the case of shape recognition, the comparison is between the sherd image and the drawing associated with the ceramic types in the Reference Database (see picture above).